As semiconductors become more highly integrated, it’s important to manage latency between processes as well as minimize wafer defects caused

by moisture, oxygen, and other substances within the wafer transport container. It is a system that quickly discharges substances that affect these

wafers to prevent a decrease in production yield.

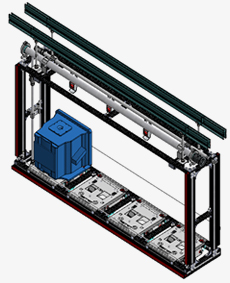

Smart Purge System

Purging function using N2 and CDA (Clean Dry Air)

Apply different recipes by frame or port

Particle removal function that can be attached to nozzles

by pre or post purge application

Minimize N2 and CDA usage with feedback control and variable purge

Zero-Foot Print maximizes production line utilization

Minimize maintenance time through pneumatic parts boardization/simplification

Support for various Inlet and Outlet combinations